|

| Frame and Skid | |

| Pump frames suffer from stress cracking and fatigue cracking at the front-end bulkhead and at the pinion, crankshaft, and bearing support areas, so we have paid particular attention to the strength of the frame and the way it's manufactured. The material is 4140 plate and the longitudinal plates have been increased by nearly 1/2" to prevent the frame from "breathing". The pump frame is machined the full length of the hold down runners at the base on either side. The skid has a fully milled flush run of 1" plate the full length. When the pump is bolted with the machined skid the stresses from the front end of the pump are transmitted through the skid, which provides added strength to the frame and a reduction in stress at the high stress points typical of other existing triplex pumps. |

Crankshaft, Pinion, Bull Gear, and Connecting Rods

The crankshaft is manufactured from a modified 4340 material with a high nickel content to reduce crack initiation and propagation. It has a high chrome content to prevent corrosion. The crankshafts are static balanced for smooth operation to reduce noise and vibration, which extends the life of the bearings and crankshaft. The Pinion and bull gear are made from similar material to the crankshaft and with a high precision double helical gear, with less backlash than any of the competitors. The precision gears ensure power is transmitted over the full width of the adjacent gears and the decreased backlash prevents the hammering effect, which occurs with speed change. The connecting rods are made from high specification Alloy Steel and machined with high precision to ensure the alignment between the crankshaft and the crosshead.

| Crossheads and Guides | Ancillary Parts | |

|

|

|

| Fluid End |

|

|

|

|

White Star ancillary parts are all considered critical to successful pump-operation. Whether it's a simple liner nut with a modified acme thread, a plug retainer or an extension rod, they are designed and manufactured to the highest standards. |

|

|

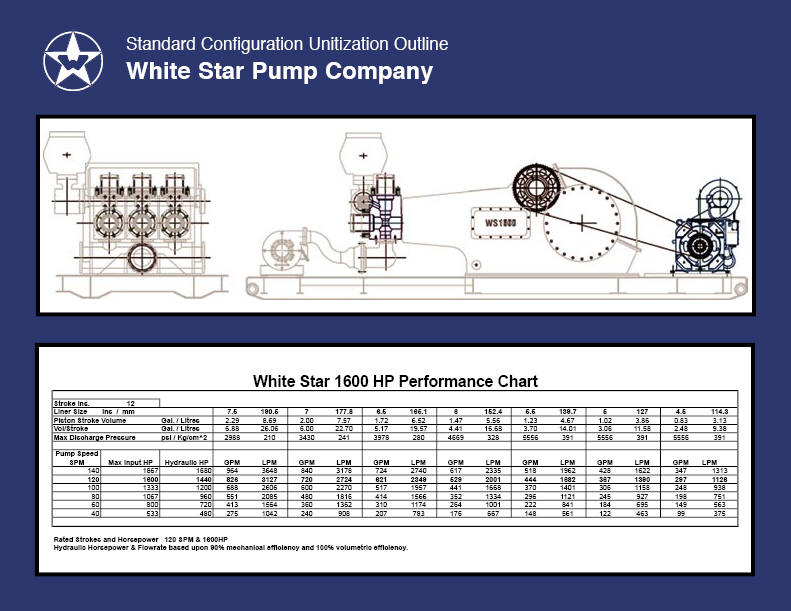

Complete Mud Systems / Parts / Services

White Star Duplex and Triplex 400, 800, 1000, 1300, 1600 horse power models are available. Complete Systems built to your specifications can be delivered within 3-4 months from their receipt. White Star offers quick turn around repair and rebuild services for their manufactured equipment as well as Ideco. Replacement parts for Ideco and White Star systems are normally shipped from inventory.

|

|

White Star's crossheads are manufactured from high quality, cast steel and the guides are manufactured from a quality manganese bronze normally used in bearings. This combination of materials provides a low friction interface and generates very little heat, which indicates no friction, which equates to no wear.

White Star's crossheads are manufactured from high quality, cast steel and the guides are manufactured from a quality manganese bronze normally used in bearings. This combination of materials provides a low friction interface and generates very little heat, which indicates no friction, which equates to no wear.