Globe Valves

Shorter disk travel - with fewer turns required to operate globe valves saves considerable time and work, also wear on valve parts.

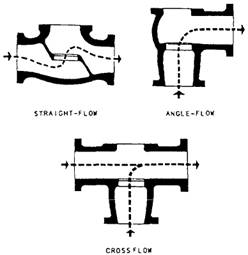

Globe valve inlet and outlet openings are arranged in several ways:

Recommended Uses:

1. Throttling service/flow regulation

2. Frequent operation

Applications: Liquids, vapors, gases, corrosive substances, slurries

Advantages: Disadvantages:

1. Efficient throttling 1. High pressure drop

2. Accurate flow control 2. More expensive than other valves

3. Available in multiple ports